If you work with pressure measurement instrumentation, you may have heard the phrases drip rings, flushing rings or calibration rings. These are used for pressure and differential pressure (DP) level measurement devices where diaphragm seals are used. I bring this up because I received an email recently that asked about these [edited and paraphrased to protect confidentiality]:

Can you advise where in the Emerson manuals they recommend the use of a Drip Ring/Calibration Ring? I am building a refinery and the specifications are not clear. The plant consists of tens of thousands of I/O and many diaphragm-type DP level and pressure transmitters. The engineering, procurement and construction (EPC) contractor has used corrosive & high pressure service criteria to determine the number of drip ring/calibration ring to be installed.

I shared this email with some colleagues and Emerson’s Satnam Singh responded to the original requestor and our team:

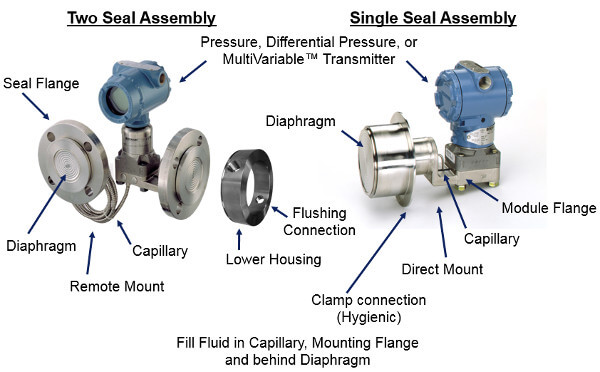

A calibration/flushing ring is a solid ring that is clamped between the process flange and the remote seal attached to a transmitter. It is used with flanged or pancake style remote diaphragm seals. Commonly, they have one or two threaded holes in the side of the ring called, “flushing connections.” It is unusual to order a calibration/flushing ring without flushing connections, but it can be used without flushing connections as a spacer or a heat dissipater.They are sometimes called flushing rings, because the flushing connections on the side of the ring allow the user access to flush out buildup on their process diaphragm. The main advantage is that you can you can perform this task without disconnecting the remote seal from the process flange.

They are sometimes called calibration rings, because the flushing connections on the side of the ring allow the user to apply a known pressure source, and consequently calibrate the unit against that known pressure. This can be accomplished by sandwiching the calibration ring between the remote seal and a blank process flange. Primarily seals are used in viscous, high temperature and corrosive application where the transmitter diaphragm is incapable of handling the process.

Satnam included this visual showing the flushing ring:

You can find more information on the use of flushing rings at Rosemount 1199 Diaphragm Seal System. These Rosemount 1199 diaphragm seals can be attached to Rosemount 3051S, 3051, 2051, 3095, and 2088 differential, gage, and absolute pressure transmitters.

You can also connect and interact with other pressure and level measurement experts in the Pressure and Level groups in the Emerson Exchange 365 community.