The failure to maintain accurate control over your chemical injection program can have a substantial impact on your profitability. Flow assurance is essential in oil and gas production, and chemical injection treatments help you achieve that by mitigating threats posed by hydrates, corrosion, scale, wax, asphaltenes and emulsions.

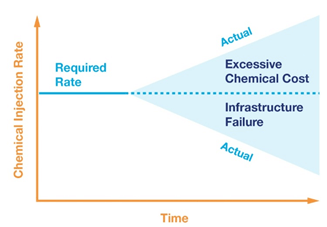

With insufficient chemical injections, these risks can impair your production. At best, this leads to expensive downtime, and at worst, it can result in the catastrophic loss of an entire asset. So, for years, the common practice has been to over-inject, but too much chemical injection can also have costly consequences. As we continue to deal with low oil and gas prices, the need to optimize the value of every operating expense is paramount.

Many production sites have been designed to allow injections over the recommended chemical dose, providing operators with older flow measurement technologies and manually adjusted controls to approximate the overdose. The biggest problem with this approach is that you cannot control what you do not measure, and without reliable and accurate flow measurement, many operators have felt obliged to spend millions in excessive chemical over-injections as a costly form of insurance against under-injection.

Many production sites have been designed to allow injections over the recommended chemical dose, providing operators with older flow measurement technologies and manually adjusted controls to approximate the overdose. The biggest problem with this approach is that you cannot control what you do not measure, and without reliable and accurate flow measurement, many operators have felt obliged to spend millions in excessive chemical over-injections as a costly form of insurance against under-injection.

The Need to Reduce Your Chemical Expense

When considering the hidden costs of traditional over-injection, we can see that this is about more than just the price of chemicals. We see an increased expense for logistics to deliver these chemicals to your sites. Headcounts are high, in order to manually monitor and control the injections. One Gulf of Mexico Operator told us “We employ one technician specifically to monitor and adjust Chemical Injection rates every four hours”. These operators are exposed more frequently during additional chemical refills, posing a risk to health, safety, and the environment.

When control is based on assumptions and a “better safe than sorry” approach, it is easy for costs to get out of control. In some cases, customers are over-injecting at rates of 20% above the recommended dose, equating to an expense of approximately €350k per chemical, per well, per year!

When control is based on assumptions and a “better safe than sorry” approach, it is easy for costs to get out of control. In some cases, customers are over-injecting at rates of 20% above the recommended dose, equating to an expense of approximately €350k per chemical, per well, per year!

Calculating this expense over the industry reveals an enormous opportunity to grow your profitability and improve your position in a very competitive market.

Chemical Injection Solutions from Emerson

At Emerson, we know how important it is to keep your operation up and running with safe and steady production. By partnering with major players in the oil and gas industry, we have developed industry-specific solutions which we can offer to help you achieve greater operational efficiency.

When traditional flow measurement products are replaced with Micro Motion Coriolis flow measurement technology, you can begin to accurately measure the dose of chemicals in your system. Coriolis meters can provide reliable measurement of mass, density, and volume simultaneously, with no moving parts, which reduces your downtime for maintenance. With Micro Motion Smart Meter Verification, you can verify meter performance without disrupting flow, saving you thousands per year in operating costs. To quote one BP operator, “We’ve shown that we can really get the reliability of the injection up by making some simple hardware improvements. We are delivering the right amount of inhibiter for the right amount of time.”

By replacing manually-adjusted control valves and regulators with an automated Tescom pressure regulation solution, you can ensure an immediate response to changing pressure conditions and maintain a precise dosing of injection chemicals. The advantage to you means no more waiting on an operator to react and manually adjust the system. With these tighter controls, your system can adapt automatically, saving you time and money.

By replacing manually-adjusted control valves and regulators with an automated Tescom pressure regulation solution, you can ensure an immediate response to changing pressure conditions and maintain a precise dosing of injection chemicals. The advantage to you means no more waiting on an operator to react and manually adjust the system. With these tighter controls, your system can adapt automatically, saving you time and money.

Contact Emerson

Interested in getting started? Let us know in the comments section or visit us here to talk with us about how a complete chemical injection solution from Emerson can help you optimize the reliability and efficiency of your installation. You can also connect and interact with other oil and gas experts in the Oil & Gas group in the Emerson Exchange 365 community.

Be sure to stay tuned for more chemical injection-related posts in the upcoming weeks.