Today on the final day of PACK EXPO 2017, Emerson’s Mike Mediana presented on the topic, Migrating from Traditional Package Sealing Technologies to Ultrasonics in Flexible Packaging Applications.

Mike’s presentation focused on how consumer preference is driving the increasing demands for flexible packaging in the medical, consumer product, and food and beverage industries. He shared how ultrasonic sealing technology helps machine builders and end users transition away from rigid to flexible packaging.

Mike’s presentation focused on how consumer preference is driving the increasing demands for flexible packaging in the medical, consumer product, and food and beverage industries. He shared how ultrasonic sealing technology helps machine builders and end users transition away from rigid to flexible packaging.

From a consumer standpoint, demand has built for packaging which supports convenience for on-the-go lifestyles, single-serve, flexible packages to reduce unused portions, and an increasing health consciousness and desire for fresh, all natural products.

For packagers, these demands translate into increased complexity. A PMMI 2015 Flexible Packaging Market assessment report highlighted some specific challenges in requirements for thinner gauge materials for pouches, new & complex shapes and designs, more frequent changeovers, and increased scrappage and waste. These challenges create operational issues including higher risk of quality issues on line or on shelf, leaking product resulting in downtime, and a greater need for operator skills.

The conventional practice of thermal package sealing has several shortcomings in trying to address these challenges. Seal failure is more likely due to contamination in seal area, variation in the materials used, and the use of thinner materials. The result is more downtime and less throughput from the packaging line due to leaking pouches, machine variation and waiting time between outages.

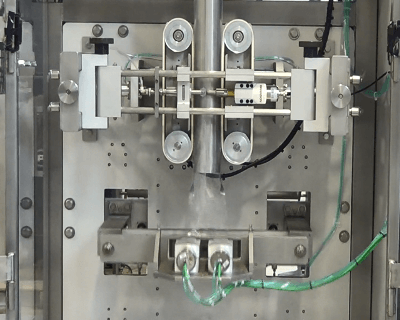

Mike contrasted ultrasonic welding technology for packaging seals from traditional thermal sealing in several areas. From a potential contamination standpoint, ultrasonic welding seals through contaminants instead of encapsulating them. From an energy usage standpoint, ultrasonic is an active cool tool process versus a conductive, hot tool process. Instead of the heat flowing through the conductor bar through the material, ultrasonic welding generates heat by friction induced by the ultrasonic frequency. As a result, it is less dependent on the material and thickness. Control of this sealing process is also more flexible using ultrasonic technology.

The result is a clean, consistent weld that is fast and efficient to keep the packaging machines productive and with much less risk of contamination. Less packaging material is also needed since the seal width can be reduced and less headspace needed between the product and the seal.

Mike noted that since packaging requirements can vary quite a bit, Emerson’s Branson brand consultants can work with packagers on performing an in-depth review of the requirements to design the right ultrasonic welding solution, which considers size and shape of the packaging, package material, product in package, weld requirements, and cycle rates.

Mike noted that since packaging requirements can vary quite a bit, Emerson’s Branson brand consultants can work with packagers on performing an in-depth review of the requirements to design the right ultrasonic welding solution, which considers size and shape of the packaging, package material, product in package, weld requirements, and cycle rates.

He shared a case study of nut butter producer which had been using a thermal sealing process. They were experiencing issues with product leakage, oil trapped in the seal area, and an excessive seal failure rate. After switching to the Branson ultrasonic welding for seals, they experienced improved weld integrity, zero seal failures in testing and a 900% increase in stores carrying their product.

He closed the presentation sharing types of applications where ultrasonic sealing technology is a good fit: continuous motion form-fill-seal, spout welding, pouch side welding and industrial valve bags.

Visit the Branson area of the Emerson website to learn more about ultrasonic welding technology and applications.