In current times where oil supply exceeds demand, storage tanks are filling. A recent Reuters article, Oil glut up close: How Cushing copes with full crude tanks notes:

Safely storing this inventory is a top priority for tank farms across the supply chain from production to final distribution. In a recent whitepaper, Benefits of Wireless Monitoring of Tank Storage Pressure Safety Valves, Emerson’s Steve Attri describes the importance of pressure management in these tanks and in providing feedback to the tank terminal operating staff to help avoid abnormal situations.There may be no better place to witness what a world awash in crude looks like, and the 9 square-mile (23.3 square km)complex seems to bear out oil traders’ fears that the industry is running out of space to contain a historic supply glut that has hammered prices.

The pressure inside these tanks can change based on changes in ambient temperature and tank levels due to filling and removal operations. Pressure is maintained within safe levels by special valves, which sense and react to small pressure changes.

Steve describes the actions of these valves [hyperlinks added]:

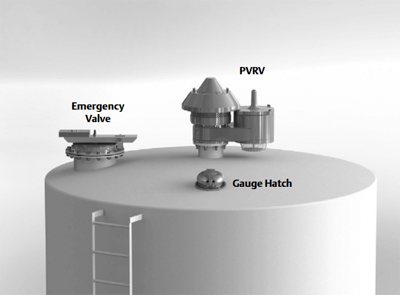

The large valve at the center is generally referred to as a pressure vacuum relief valve or PVRV, for short. This device contains weighted pallets which will open and close based on pressure. If the pressure inside the tank rises above the set point, the pressure pallet will open, releasing vapors in order to return the pressure to a safe level. Conversely, if the pressure inside the tank drops below a preset level, the vacuum pallet will move open, bringing air into the tank to return the pressure to a safe level.

The device shown on the left… is called an emergency valve or vent. If an abnormal pressure situation occurs, this vent will quickly relieve tank pressure. Under normal conditions, it should be closed. Note that the small device shown near the front of the tank is a gauge hatch, which is for inspection and gauging purposes.

While these safety devices automatically perform this pressure management function, historically they have been isolated and not connected to feedback any problems back to the operations staff. In fact, a study conducted by Emerson found that:

Maintenance involves climbing tanks into these hazardous locations and trying to spot problems before they might lead to environmental emissions or damage to the tank itself. Using wireless technology proven in operation since 2008, a wireless pressure vacuum relief valve allows continuous monitoring of open/close status of the valve to help determine proper pressure system operation.…an undetected maintenance issue is the number one concern of tank safety engineers and managers. More than half (54%) reported more than one pressure control issue in a year. In addition, 65% of the time, these issues were being detected after the fact.

The wireless transmitter connects to the pressure and/or vacuum sides of the PVRV and has proximity sensors that allow the transmitter to detect the open or closed position of the vents.

Steve describes some scenarios. For some tanks, redundant PVRVs are used for added safety:

If the primary PVRV fails in a closed or partially closed position, then the backup PVRV automatically takes over. This is achieved by establishing a pressure set point that is slightly higher for the backup device. In this way, if the primary PVRV fails, the tank remains protected but redundancy is lost and should be addressed as soon as possible.

With remote monitoring added, the position of the backup PVRV helps spot this issue on either the pressure or vacuum side.

Under normal conditions, the backup PVRV remains closed. If the backup PVRV is open, this points to either the primary PVRV not functioning as expected or a separate pressure control problem in the tank system that is causing both PVRV’s to be open.

Read the whitepaper to see other scenarios including tank blanketing and emergency venting for more on how wireless PVRVs can help improve safe operations, reduce unintended emissions and protect the assets both inside the tank and with the tank itself.

You can connect and interact with other pressure regulator experts in the Regulators group in the Emerson Exchange 365 community.