This past week, researchers at MIT were published in MIT News about a new approach to monetizing coal for power plants by combining coal gasification with fuel cell technology.

By dovetailing these two systems, the research states that efficiencies could approach 60 percent, nearing those achieved in modern combined cycle plants. And, like combined cycle plants, this technology yields about half of the CO2 per given unit of electricity produced. I read the article and thought, that’s a great idea, but can this design actually be viable for today’s power grid?

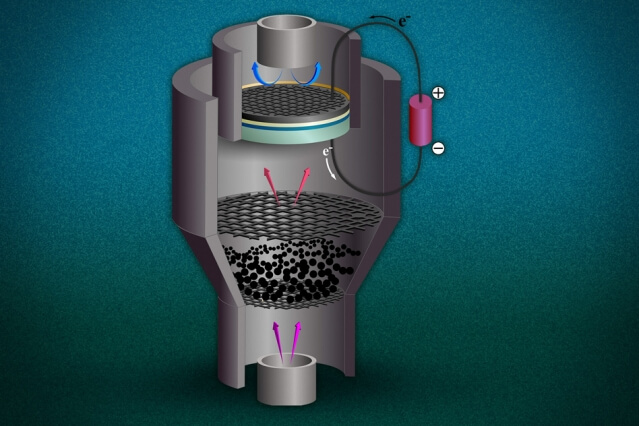

Source: MIT News–This illustration depicts a possible configuration for the combined system proposed by MIT researchers. At the bottom, steam (pink arrows) passes through pulverized coal, releasing gaseous fuel (red arrows) made up of hydrogen and carbon monoxide. This fuel goes into a solid oxide fuel cell (disks near top), where it reacts with oxygen from the air (blue arrows) to produce electricity (loop at right). Illustration: Jeffrey Hanna

But one question is whether or not something that works thermodynamically on paper can actually help with the delivery of power. In today’s world, new thermal generation has to be able to balance the irregular supply of renewables…that means it needs to be able to cycle load while being cost effective.

Let’s focus on the gasification process itself. Although there are many different approaches to gasification, they all work best in steady state operation, such as in the coal to chemical industry in China. Gasifiers do not react quickly to changes so requiring one to move load regularly would be problematic.

On top of this, gasification plants are more expensive to build than traditional thermal power and the process is much more challenging from an operations standpoint (think “chemical plant” more than “power plant”). Process equipment in gasification wears faster, and as a result, the cost of operations is higher because of the continual need for refurbishment. Staffing requirements and safety systems are also more extensive and costly.

Gasification is already used in power and the two most recent examples of Integrated Gasification Combined Cycle (IGCC) plants prove its complexity. Both the Duke Edwardsport and Southern Company’s Kemper County projects greatly exceeded their original budgets. A rule of thumb is that first of a kind technology ends up costing about 3 times the original budget and these projects proved this as they are at/above the capital cost of a typical nuclear power plant.

Perhaps a more practical approach to reducing emissions with coal is to continue to push already proven ultra-supercritical plants. These are a mainstay in China and are being constructed in India and the Middle East. Their capital cost is slightly more expensive that drum coal plants, but their efficiencies improve by about 10 percent. This increase represents a significant reduction in emissions as one point of efficiency improvement provides a two to three percent reduction in CO2 while also reducing NOx and SOx.

It will be years before this very unique MIT design will be tested commercially, and in the meantime, ultra-supercritical plants will continue to be built around the world. The cost of these plants will decline as more are constructed and their efficiencies will continue to be pushed higher.

From Jim: You can connect and interact with other power generation experts in the Power group in the Emerson Exchange 365 community.