One of the earliest applications of “computer control”, a now archaic term, on an ammonia plant was done in 1969 by Weissenfelder and Shah of Borden Chemical and IBM respectively. They were able to implement advanced control schemes in a computer that had proven to be too difficult to do in the pneumatic and electronic controllers of the time. Ammonia production increased, costs went down and the plant operators had better information to make decisions.

I followed A.J. Weissenfelder at Borden Chemical in 1977 and one of the first things I found was that it was so much easier to modify the advanced control schemes on the computer than trying to change the configuration of board instruments. Modifications that were required because of plant changes, modernizations, etc. could be, and were, quickly implemented.

Today we implement control schemes very similar to what Weissenfelder and Shah did but with vastly improved tools that have made the control schemes even easier to implement and much easier to modify. Further, many control system suppliers and consultants have packaged ammonia control schemes to allow proven solutions to be implemented very quickly.

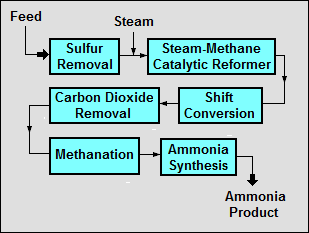

The packages for the steam-methane reformer, for example, have the same control objectives as the early computer control schemes—maximize throughput, reduce methane leakage to a minimum and minimize fuel consumption. A steam-methane reformer reacts steam and methane over a catalyst to produce hydrogen, carbon monoxide (CO) and carbon dioxide (CO2). The same reaction and control objectives are found in hydrogen plants and methanol plants. The steam-methane reformer package can be made generic, reducing costs and prices.No production manager in an ammonia plant would be satisfied operating at nameplate capacity. If the nameplate says 2,200 tons per day, he will push the plant to produce more, of course. The limit is some constraint in the process—ambient conditions, capacity, temperatures, etc. To operate at the higher-than-nameplate rate often requires adjustment to the control package used on the steam-methane reformer.

An example, in hot climates, cooling water can be a constraint for an ammonia plant. Cooling water is used in the CO2 removal system. Any oxygen-containing molecule (CO, CO2, H2O) will poison the catalyst used to produce ammonia so the goal is to make sure that we minimize the amount of these poisons in the feed to the reactor. CO is converted to CO2 in the shift-reactor section then the combined CO2 is removed in the CO2 removal system.

An example, in hot climates, cooling water can be a constraint for an ammonia plant. Cooling water is used in the CO2 removal system. Any oxygen-containing molecule (CO, CO2, H2O) will poison the catalyst used to produce ammonia so the goal is to make sure that we minimize the amount of these poisons in the feed to the reactor. CO is converted to CO2 in the shift-reactor section then the combined CO2 is removed in the CO2 removal system.

Any CO or CO2 that slips through is handled by the methanol section. In the methanator, the reaction used in the reformer to produce hydrogen is reversed, converting hydrogen and CO2 to methane. When there is not enough cooling water, much more CO2 slips through and the methanator uses a lot of hydrogen to make methane. In the reformer, we are pushing to limits to maximize the amount of methane converted to hydrogen by firing harder. In the methanol, we then produce more methane by consuming hydrogen. The rest is wasted energy and a reformer being pushed to limits unnecessarily.

The solution is to let the reformer “know about” the methanator problem. The reaction making hydrogen in the reformer is endothermic (requires heat) while the reaction in the methanator is exothermic (produces heat). By measuring the temperature rise across the methanator, we can get an idea of how much CO2 is being converted into methane. Adding this value (methanator delta-T) to the reformer package’s constraints adjusts the reformer to compensate for the efficiency problem of making hydrogen at one end of the plant and reversing the reaction at the other end of the plant.

This is not a solution that is necessary in many ammonia plants (and not needed at all in hydrogen and methanol plants), so, making it part of the steam-methane reformer package is not really an option. Being able to easily modify the advanced control to handle new constraints and problems in the ammonia plant is the solution. In packages like multivariable controller in DeltaV (used for the steam-methane reformer package), the configuration and testing tools are easily accessible to allow the particular ammonia plant to adjust to the particular problems it faces.

Process improvement and optimization consultants can help you find opportunities to improve energy efficiency, reliability and the overall availability of your ammonia production process.

From Jim: You can also connect and interact with other advanced control experts in the Improve & Modernize and DeltaV groups in the Emerson Exchange 365 community.