Moving from the theoretical world of proportional-integral-derivative control to applying it successfully is a hurdle new process control engineers face. Once mastered, the next step might be in applying advanced process controls. Model predictive control, neural networks, fuzzy logic, gain scheduling and more each require bandwidth and experience to master.

One great way to climb the learning curve is to hear from a seasoned practitioner. For users with DeltaV distributed control systems, an upcoming opportunity is to catch principal process consultant, James Beall, at the October 24-28 Emerson Exchange conference in Austin. James will be presenting a workshop on model predictive control (MPC). Here is the abstract from this workshop, Getting Started with DeltaV MPC – Tips and Techniques:

Do you want to implement DeltaV MPC but don’t know where to start? This workshop will explain how to select small applications for DeltaV MPC, how to calculate potential benefits and how the DeltaV MPC works in easy-to-understand terms. Field proven practical tips and techniques to implement MPC will be explained. This information will be worth years of experience in applying DeltaV MPC!

…an advanced method of process control that has been in use in the process industries in chemical plants and oil refineries since the 1980s. In recent years it has also been used in power system balancing models.[1] Model predictive controllers rely on dynamic models of the process, most often linear empirical models obtained by system identification. The main advantage of MPC is the fact that it allows the current timeslot to be optimized, while keeping future timeslots in account. This is achieved by optimizing a finite time-horizon, but only implementing the current timeslot. MPC has the ability to anticipate future events and can take control actions accordingly.

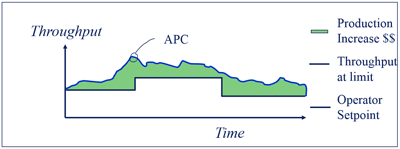

James will share how MPCs can provide significant economic benefit by reducing variability, increasing capacity, reducing energy usage and more. One small MPC project that he completed with less than 3 weeks of effort resulted in over $200K/year of energy savings. His practical tips and techniques explained in this workshop will allow you to implement DeltaV MPC easier and faster.

James will share how MPCs can provide significant economic benefit by reducing variability, increasing capacity, reducing energy usage and more. One small MPC project that he completed with less than 3 weeks of effort resulted in over $200K/year of energy savings. His practical tips and techniques explained in this workshop will allow you to implement DeltaV MPC easier and faster.

Implementing your first MPC application can be a challenging task. There are many configuration options and “tuning” settings that can affect the MPC performance. Often the default setting for these parameters do not achieve the desired performance from the MPC. Custom settings for these parameters are essential to achieve the desired response and performance from the DeltaV embedded MPC.

The focus of this workshop will be to explain how the DeltaV MPC works in easy-to-understand terms. James will explain the impact of key MPC parameters such as the dynamic controller setup, penalty on move, penalty on error, optimization priorities, etc. He’ll outline techniques to calculate benefits and field proven practical tips and techniques to successfully implement MPC.

It sounds like a session you don’t want to miss. If you register by September 30, you can save $200 off the conference registration fee. If you can’t make it, I’ll see if I can follow up with a blog post with some of the tips and techniques that James shares. You can also connect and interact with other advanced process control experts in the Improve & Modernize, DeltaV and Ovation groups in the Emerson Exchange 365 community.