Sonal Gilani

Chemical Industry Program Manager

In an earlier post, Improving Energy Efficiency in Thermal Oxidizers, I highlighted how switching control loops from manual to automatic mode improved overall efficiency.

James Beall

Principal Process Control Consultant

This particular plant encountered a situation after a migration of the control system such that they could not run the thermal oxidizer with all the loops in auto. They had repaired instrumentation, reconditioned control valves and tuned the controllers but could not get all the key controllers to run in auto.

In this process, the waste heat from the flue gases of this thermal oxidizer is recovered through a thermal oil heat exchanger. This recovered heat is used in several plant operating units. Maintaining constant outlet temperature of the heated thermal oil is very important for its usage in the plant.

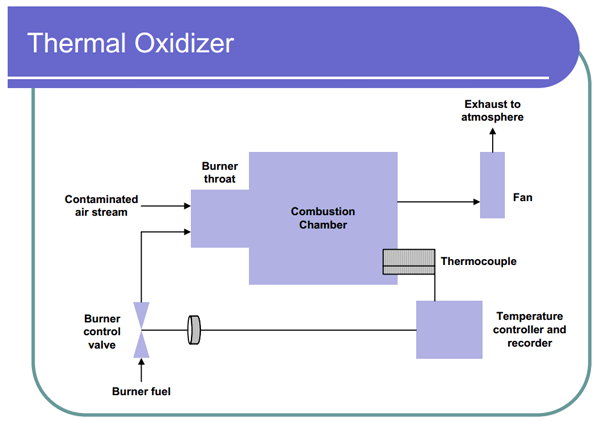

Source: U.S. Environmental Protection Agency, Schematic of a Basic Thermal Incinerator

Operation of the thermal oxidizer unit in manual control resulted in fluctuation of the thermal oil temperature by ±3°C which caused process disturbances in the other operating units in the plant. Operating in manual mode also resulted in excessive use of natural gas. As a member of the Control Performance Consulting team, James was brought in to investigate the causes of this high variability and energy inefficient situation.

James recognized very quickly that the problem lay in the interaction of the key control loops. The six control loops—burner temperature control, oxidation section temperature differential control, fuel flow control, combustion air flow control, hot oil outlet temperature control and excess oxygen in the flue gas control are critical to stable operation of the oxidizer.

These key loops needed to be tuned to respond in a coordinated manner. This was a classic example of interacting control loops for which the solution is coordinated loop tuning using the Lambda tuning methodology. James tuned the loops using the Entech Toolkit and within two days onsite, all the control loops on the thermal oxidizer were running in auto.

The automatic operation reduced the variability of the temperature of thermal oil at the outlet of heat exchanger by a factor of ten, from ±3°C to ±0.3°C. This consistent outlet temperature of the thermal oil also ensured reduced variability and optimum performance of the controls of other processes in the plant that use this thermal oil for heating. Additionally this helped save natural gas cost by about $50,000 per year incurred by the plant which directly contributed to its bottom line.

From Jim: You can connect and interact with other chemical industry and optimization professionals in the Chemical and Operate & Maintain groups in the Emerson Exchange 365 community.