In earlier posts, we’ve highlighted the use of bunker fuel for marine vessels. With the global trend for increased supplies and decreased costs of natural gas and tightening environmental regulations, marine transportation companies are looking at cleaner burning liquefied natural gas (LNG) as an alternative to the heavy fuel oil.

At the recent Lloyd’s Maritime Academy event, Bunkering and Infrastructure for LNG Fuelled Vessels, Emerson’s Arjan van Ginkel presented on the topic of LNG bunkering solutions. He opened noting the environmental milestones through the International Maritime Organization‘s MARPOL (International Convention for the Prevention of Pollution from Ships) and sulfur limits established by Annex VI Regulations. Here are some sulfur oxides regulatory deadlines:

|

Outside an ECA established to limit SOx and particulate matter emissions |

Inside an ECA established to limit SOx and particulate matter emissions |

|

4.50% m/m prior to 1 January 2012 |

1.50% m/m prior to 1 July 2010 |

|

3.50% m/m on and after 1 January 2012 |

1.00% m/m on and after 1 July 2010 |

|

0.50% m/m on and after 1 January 2020* |

0.10% m/m on and after 1 January 2015 |

Arjan noted some of the benefits of LNG as a fuel source. It is less expensive than heavy fuel oil or low-sulfur fuels. It is becoming increasingly available as LNG facilities are built to normalize natural gas supplies and prices around the globe. The liquefaction process compresses the volume by a factor of 600. This liquefaction process also freezes non-fuel gases such as CO2 to purify the fuel.

He cited an MEC Intelligence Report highlighting the savings potential of LNG over heavy fuel oil with scrubbers or marine gas oil (MGO). The report’s press release shared:

The LNG propulsion technology will potentially gain massive traction in the new build segment owing to significantly lower operation costs leading to a lower total ownership cost over the ship’s lifecycle. The total ownership cost over ship’s lifecycle for a new build LNG propelled vessel (depending on vessel type and geography) is expected to be up to 40% lower as compared to that of a fuel oil and MGO propelled vessel.

With LNG as the fuel source, accuracy in the fuel’s custody transfer is critical. In Europe, custody transfer applications are governed by the Measuring Instruments Directive (MID) and OIML is the global standard for guaranteeing the accuracy of the measuring system performing the custody transfer of the LNG fuel. We’ve highlighted some of the certified mass-based marine bunker measurement equipment that can be used in an earlier post, Efficient Consumption of Heavy Fuel Oil in Shipping Operations.

Arjan highlighted the importance of measuring mass instead of volume to avoid the impact (on volume) of pressure and temperature. Energy content (mega joules per kilogram) is measured in gross caloric value, for which a gas density meter may serve. And the quality of the fuel, or methane number, is measured by a gas chromatograph. The custody transfer needs to be done per the MID/OIML regulations.

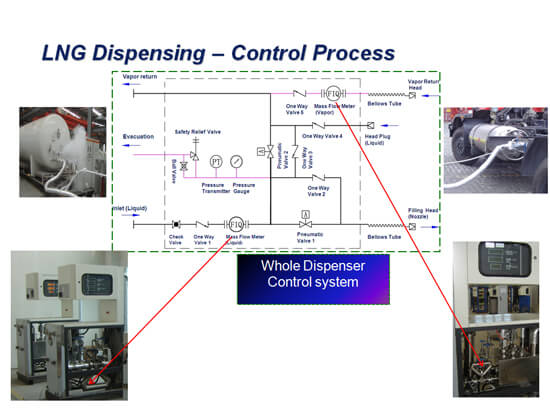

Coriolis flow and density meters play a key role in meeting these requirements. Here’s the P&ID for the LNG dispensing process:

Fuel economics and global emissions standards will continue to reshape transportation fuels and highly accurate measurement technologies will continue to play a key role in the exchange of fuels between buyer and seller. If your process involves the transfer of LNG fuels, see the presentation for the full story.

| iTunes