Emerson’s Alan Novak, leader of the alternative energy industry team, highlights technology changes that may replace the need for water in hydraulic fracturing.

In a previous post, we discussed the process of Hydraulic Fracturing, or “Fracking”, which is used to recover natural gas from shale formations.

While fracking has unlocked immense reserves of natural gas in the US and elsewhere, concerns have surfaced over both the amount of water required by the process (fracturing a well can use as much as 5 million gallons of water) and the treatment and disposal of wastewater which returns from the well. Water may dissolve salts or pick up naturally occurring radioactive elements in the shale formation and return them to the surface.

Concerns can become so great that individual states step in to temporarily halt development. In mid-2010, the NY legislature approved a moratorium on new fracking permits. The NY moratorium was driven in part by concerns over treatment and disposal of wastewater.

As highlighted in a recent Reuters article, a technology has emerged which may eliminate the use of water while at the same time providing better recovery and faster production from shale gas reservoirs.

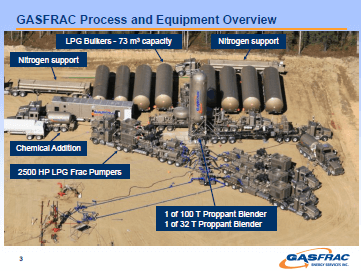

A relatively new company (founded in 2006), GasFrac, has developed a process which uses gelled Liquefied Petroleum Gas (LPG) in place of water to hydraulically fracture shale gas wells.

From: www.gasfrac.com/assets/docs/PDFS/presentations/Investor Presentation - Realizing the Potential.pdf

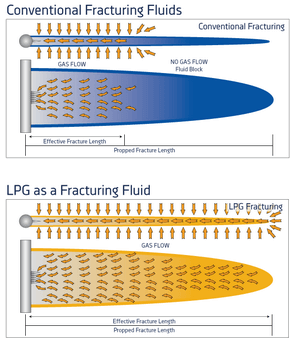

LPG offers several advantages. No process water or wastewater is required; it is an inert fluid which does not dissolve undesirable underground elements; it allows the hydrocarbons already being produced to be used for further production; and, according to GasFrac’s data, it provides faster well start up and higher production rates.Here is a comparison on effective fracturing lengths between water and LPG.

Will waterless fracking be the next big thing in shale gas development? Only time will tell, but it is clear that the energy industry will remain a dynamic market.