An industry commitment and new technologies are contributing to cleaner metals and mining operations. Emerson’s Michael Pearson, a member of the Rosemount Measurement team and metals and mining industry team, shares examples of the progress being made.

Mining and metal refining are considered some of the most environmentally friendly processes, championed by communities and environmental groups alike. Well… That’s the goal anyway. In reality, mining has often been considered an environmental nightmare. Mines all over the world often face much scrutiny from governments and communities due to the potential for pollution, resource depletion, and environmental destruction.

Increased scrutiny is deserved, as the mining industry has a long history of environmental issues. However, things are changing! Over the past decade, governments, universities, environmental groups and mining companies have begun to work together to promote the advancement of clean mining technologies, sustainability, and waste mitigation.

Most major mining companies have plans in place to improve sustainable development. Freeport-McMoRan’s approach for example includes compliance with the Global Reporting Initiative (G3). G3’s sustainability Performance Indicators are organized into categories: Economic, Environmental and Social. The Social category is broken down further by Labor, Human Rights, Society and Product Responsibility subcategories.

Advancement in mining technology has also led to dramatic increases in sustainability. For example, Chile’s state mining company, Codelco, has recently announced a new method for metal extraction, which uses organic materials instead of the more traditional cyanide to remove copper from rock.

In addition to new mining technologies, part of an effective environmental plan involves monitoring and reporting of key performance factors—as well as reducing energy usage. Many measurement solutions used in other industries can be applied to the mining industry. One example is greenhouse gas emissions from smelters.

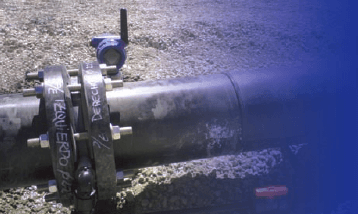

Met-Mex Peñoles applied wireless technology with Rosemount Annubar flow meters to monitor and report their sulfur dioxide (SO2) emissions. The new method allows them to reduce emissions and prove compliance with environmental regulations. Other examples of using technology to improve sustainability include Barrick Zaldivar’s use of IEC 62591 wireless flow devices to decrease acid consumption, or Tata Steel’s integrated safety, emissions and energy reduction solution.Mining is an important and necessary part of our industrialized world. Although it has historically been damaging to the environment, progress is being made. Mining companies and communities are taking steps to improve mining efficiency and reduce its effects on the environment. Measurement automation technology allows companies to innovate upon and improve their mining and metals operations. The road will not be short, but progress is being made, and the future of sustainable metal production looks bright.