I just saw in Neal Ingram’s Micro Motion Community blog the news about marine bunker measurement shared at last week’s 2011 Nor-Shipping Exhibition and Maritime Conference in Norway. This topic is something we highlighted a while back in a post, Accurate Measurement of Bunker Delivery Quantities. Bunker fuel or heavy fuel oil (HFO) is:

…also known by other names: heavy oil, #6 oil, resid, Bunker C, blended fuel oil, furnace oil and other often locally used names. No matter the origin of bunker fuel it has common properties where ever found: color, viscosity, contaminants, and operator problems.

Custody transfers of this fuel at various stages of the supply chain from fuel storage to barge to operating vessels has been a difficult process because these billings have been based upon the mass of the transferred fuel. Volumetric measurement has historically been used. This method relies on lookup tables and lab tests to determine the density of the bunker fuel to calculate the mass. The density, viscosity, and entrained air quantity can vary greatly, significantly impacting the measurement. Also, the fuel may separate into layers in the storage tank, which also impacts measurement accuracy. A correction factor needs to compensate for these challenges to convert the measurement into the mass measurement required for the billing process.

Custody transfers of this fuel at various stages of the supply chain from fuel storage to barge to operating vessels has been a difficult process because these billings have been based upon the mass of the transferred fuel. Volumetric measurement has historically been used. This method relies on lookup tables and lab tests to determine the density of the bunker fuel to calculate the mass. The density, viscosity, and entrained air quantity can vary greatly, significantly impacting the measurement. Also, the fuel may separate into layers in the storage tank, which also impacts measurement accuracy. A correction factor needs to compensate for these challenges to convert the measurement into the mass measurement required for the billing process.

I checked with Emerson’s Steve Jones on the news of the certified, mass-based measurement that the Micro Motion team received for this marine bunkering application. He cited a Bunkerworld statistic that the amount of official industry-wide global bunkering disputes in 2009 was over 50,000 incidents. Bunker fuel costs can amount to 50-70% of a ship’s operating expenses. This indirect way of measuring mass was a real problem for the industry.

Steve described the use of Coriolis massed-based measurement as a global, transparent and traceable bunker measurement solution across the complete supply chain. Mass-based measurement is insensitive to temperature, pressure, and density.

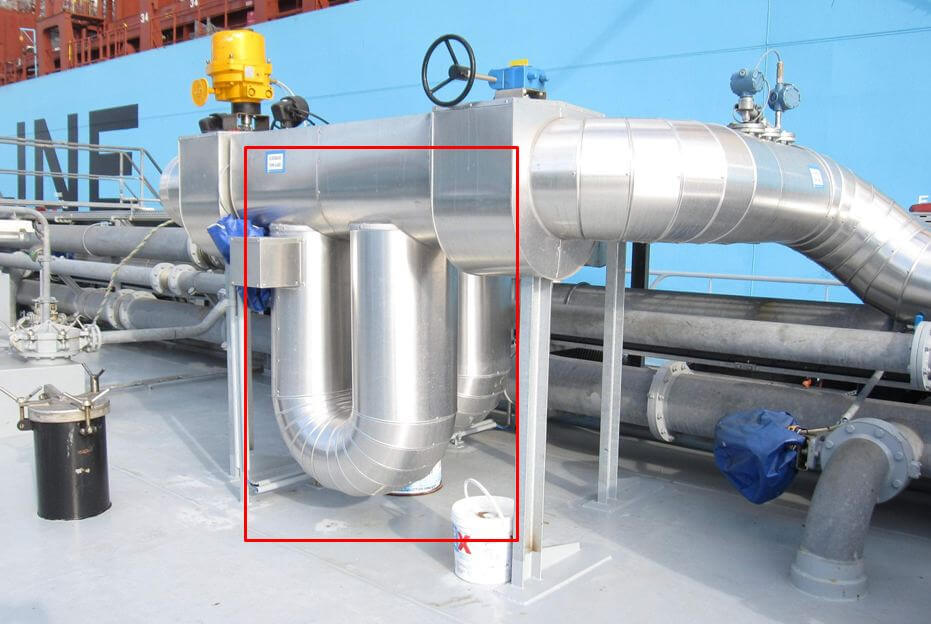

The Certified Marine Bunker Measurement Solution includes a Micro Motion Elite Coriolis meter, Series 3000 transmitter with Marine Bunker Transfer Package, and bunker delivery ticket printer. The solution is capable of handling the density and viscosity variation inherent in HFO and was certified by Nederlands Meetinstituut (NMi), the notified body for testing to the guidelines of the European Instruments Directive (MID) and Issuing Authority for OIML (International Organization for Legal Metrology). The Micro Motion meter meets the OIML standard R117-1 and the overall solution meets MID standard 2004/22/EC Annex MI-005.

The Certified Marine Bunker Measurement Solution includes a Micro Motion Elite Coriolis meter, Series 3000 transmitter with Marine Bunker Transfer Package, and bunker delivery ticket printer. The solution is capable of handling the density and viscosity variation inherent in HFO and was certified by Nederlands Meetinstituut (NMi), the notified body for testing to the guidelines of the European Instruments Directive (MID) and Issuing Authority for OIML (International Organization for Legal Metrology). The Micro Motion meter meets the OIML standard R117-1 and the overall solution meets MID standard 2004/22/EC Annex MI-005.

The intent of these standards is to provide an overall set of requirements that need to be followed to guarantee that custody transfer receivers are getting what they are paying for and that they can prove it. For custody transfer senders, they are delivering what they are being paid for and they can prove it.

Hopefully, this solution can make a dent in those 50,000+ disputes as fuel storage terminals, barges, and operating vessels switch over from volumetric-based to mass-based custody transfer measurement. Perhaps everyone but the lawyers will see this as a positive development.