Imagine leaving some of your portable electronics out on a hot day. Now imagine leaving it out in a desert in the Middle East in the middle of an extremely hot summer. How long do you think it would last?

Emerson’s David Walker told the story, DeltaV SIS in the Heat of the Desert, at the recent Emerson Exchange. A major oil and gas producer had experience with field-installed DeltaV and PROVOX control systems, but not with the DeltaV SIS (safety instrumented system).

The oil & gas producer wanted to be able to locate the equipment outside by the production equipment, in a cabinet out in direct sunlight. The DeltaV SIS equipment, rated for 70˚C (158˚F) operating temperatures would be put to the test to see if it could hold up to extreme heat desert conditions without any supplemental cooling systems.

The system was located in a small cabinet housing in a Zone 2 hazardous area location. The cabinet contained DeltaV SIS logic solvers, DeltaV controllers, SISNet Repeaters, cabinet temperature monitoring, and connections to a DVC6000 SIS controlling the safety shutdown valve and the safety instrumented function (SIF) sensors. Economics drove the decision to test the equipment in these conditions. By locating the SIS close to the production equipment, field wiring and cable could be reduced, less cable tray would be required, less marshalling panels and wiring would be needed, and a lower footprint would be consumed in the rack room.

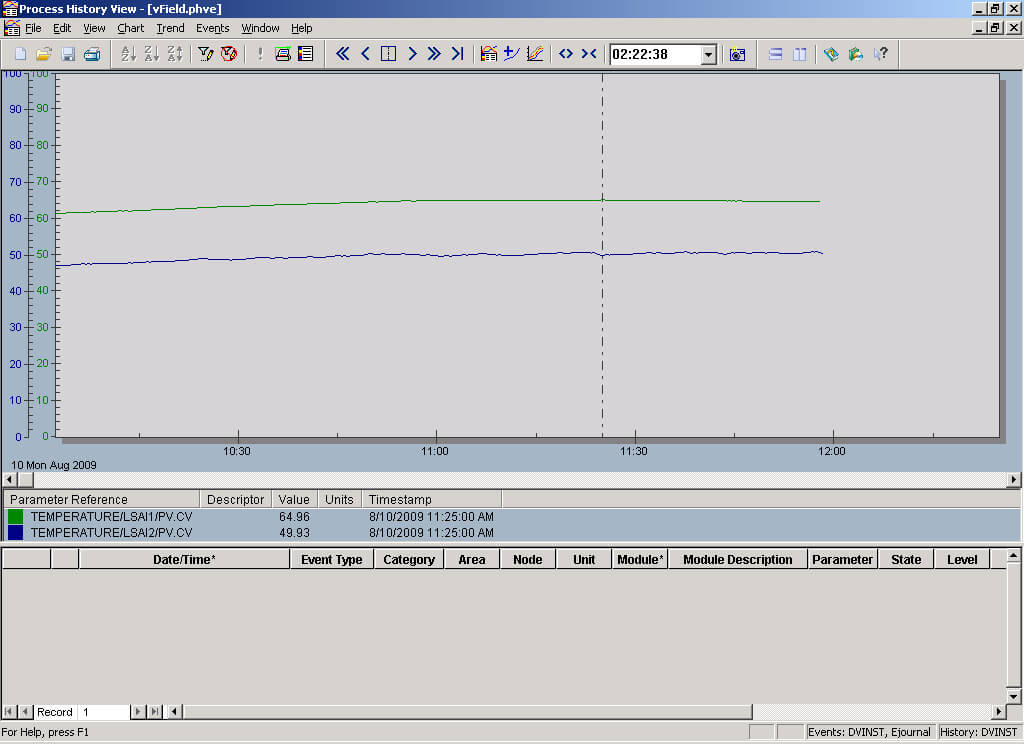

David showed a temperature trend chart over a six-month span the ranged from 10˚C up to around 60˚C, with a peak temperature of 65˚C inside the cabinet.

Besides the reduced capital costs, the production team wanted to be able to use wireless technologies to perform partial stroke tests on the safety valves and view the process and diagnostic information from a mobile, ruggedized PC. This also led to capital savings since local control panels would not be required at the production equipment. The mobile PCs could also support the ongoing proof testing activities using AMS Device Manager and Syncade operations management software. The partial stoke testing could be performed automatically from the DeltaV SIS logic solver or manually either next to the safety valve, back inside the control room, or remotely from a safe location.

After two years of successful run time, the DeltaV SIS was approved by the oil and gas producer for wider use in emergency shutdown applications across many different types of processes and environmental conditions.

Update: Welcome to the readers of the Emerson Process Libya blog. Thanks for visiting and I hope you’ll come back!