Adsorption, different from absorption, is the process of the:

…adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface.[1]

In process manufacturing operations, adsorption is sometimes used in dehydration or purification processes. In the oil & gas industry, this method is used to dehydrate and remove contaminants from natural gas.

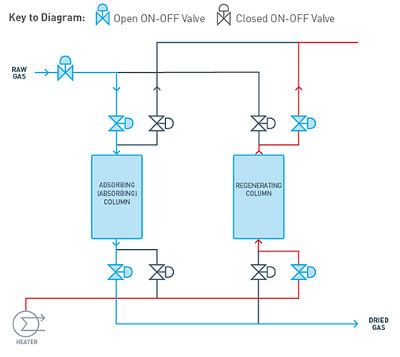

At next week’s 2018 Offshore Technology Conference (OTC), Emerson’s David Leavitt will present a paper co-written with Marco Ferrara and Sergio Casaroli, Triple Offset Valves in Molecular Sieve Processes, as part of the Topside Innovative Processing and Design technical track.Molecular sieves are made from a micro-porous material to selectively adsorb gases and liquids. They operate in an adsorbing (purification) mode and a regeneration mode, which recovers the solid and liquid molecules trapped during the adsorption phase. The regeneration mode uses large swings in temperature to free the trapped molecules.

This process switching between adsorption and regeneration is very hard on the valves controlling the flow, due to the frequency of on and off switching. Failure of a valve can affect safety, emissions and production.

Typically, adsorption columns come in pairs where one operates in adsorption mode while the other regenerates. They may cycle back and forth 24 cycles per day with thermal cycles up to 600°F/315°C. Beyond the frequent cycling and thermal stresses, the valves can be exposed to corrosive gases and residuals in some non-pretreated gas applications.

Typically, adsorption columns come in pairs where one operates in adsorption mode while the other regenerates. They may cycle back and forth 24 cycles per day with thermal cycles up to 600°F/315°C. Beyond the frequent cycling and thermal stresses, the valves can be exposed to corrosive gases and residuals in some non-pretreated gas applications.

Rising stem (tilting) ball valves have historically been used in this application. At larger sizes and pressure classes, these valves have a large footprint and are extremely heavy. The tilting mechanism wears and degenerates over time.

Triple offset valves (TOVs) are well suited for molecular sieve applications from a reliability and cost standpoint. They are designed to provide zero leakage (no visible leakage when tested at high pressure with water and low pressure with air per international standards).

TOV technology can handle bidirectional flow and tight seals in both flow directions. With flexible metal seal rings, they withstand high frequency open-close cycling. The non-rubbing design eliminates wear between sealing components. From a large temperature swing standpoint, metal-to-metal sealing, a resilient seal ring and torque seating maintain seal tightness during thermal and pressure cycles.

In addition to molecular sieve applications, TOVs are well suited for liquefied natural gas (LNG) processes, air separator units (air dehydrators), and ethylene plant cracked gas drying applications, to name a few.

If you’ll be attending OTC2018, make sure to catch David’s presentation at 10:55am on Monday and see this and other Emerson technologies in the OTC exhibit area in the Emerson booth #2261. Visit the Offshore Technology Conference 2018 page on Emerson.com to get a free show pass.

You can also connect and interact with other valve and oil & gas industry experts in the Valves and Oil & Gas groups in the Emerson Exchange 365 community.