Olefins, also known as alkenes, are unsaturated hydrocarbons, use to make many petrochemical products such as plastics. Olefin production, including ethylene, propylene and butadiene products, requires tight control for higher throughput, more energy efficient, and more reliable operations.

In an article from The Chemical Engineer, Increasing Ethylene Conversion and Plant Reliability, Emerson’s Blake Coleman describes each of the key processing areas in olefin production and what are critical factors when selecting control valves for reliable and efficient performance.

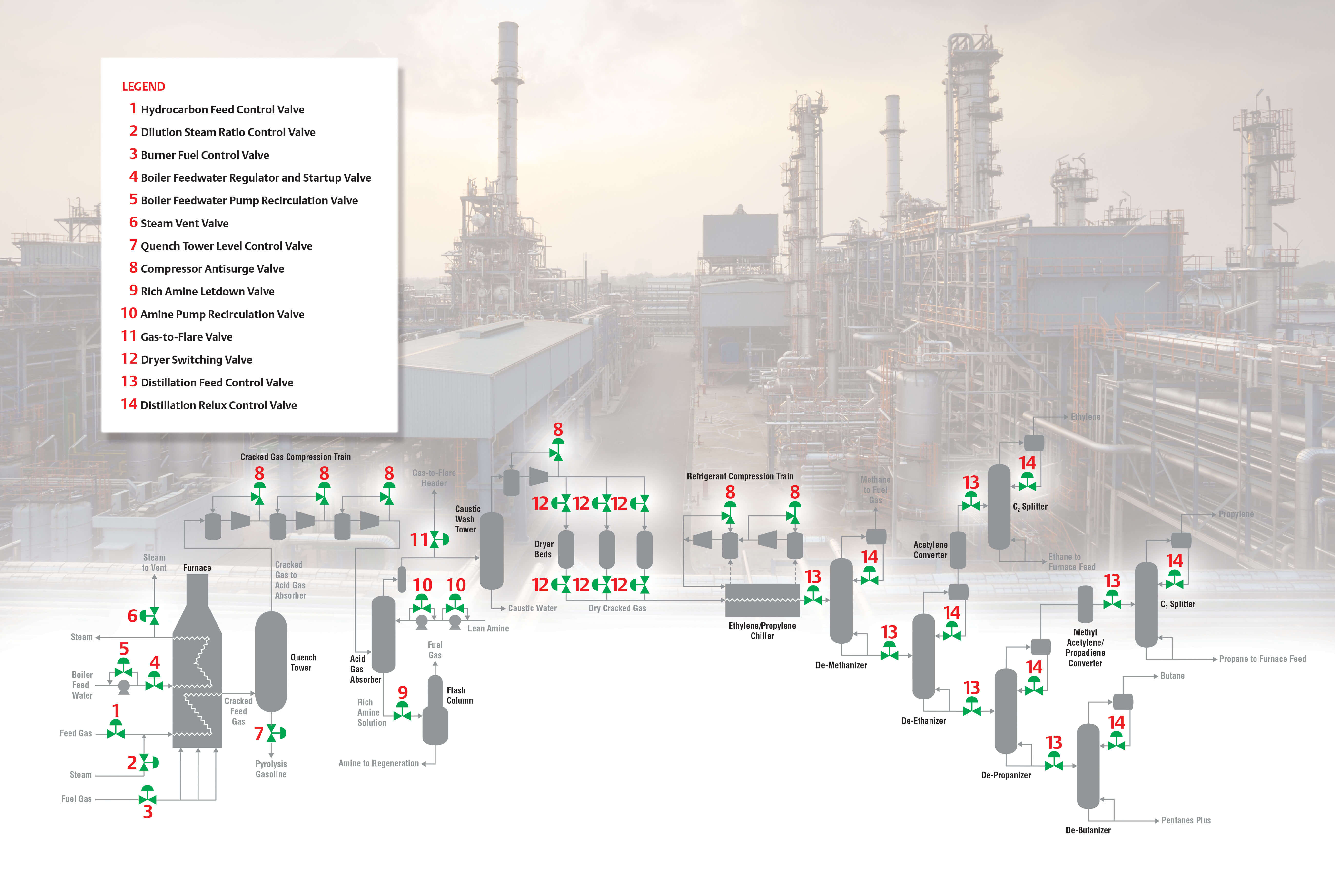

Blake opens describing the production process as consisting of:

…three main areas: a hot section, where the reaction takes place; a compressor section, that provides the necessary pressure to move feedstock through the plant and provide refrigeration; and the recovery section, where product is distilled at low cryogenic temperatures can be found.

In the hot section where non-optimal control can lead to cracking tubes and fouling, several control valves are key.

Feedstock flow control valves and steam feed valves are critical control points that have a direct impact on furnace performance… The feed rate must be balanced with dilution steam to lower hydrocarbon partial pressure and increase olefin yield. Several valves are commonly used to control the flow of feedstock into the furnace. Reliability is the foremost consideration of inlet feed valves.

He shares some important selection considerations for the valves:

- spring-and-diaphragm actuators increase stability

- digital valve controllers with online diagnostics monitor real-time performance changes

- sliding-stem body designs offer precise control

- noise-reducing trims minimise aerodynamic noise

- customisable trim options meet a wide range of operating conditions

- hardened trim materials provide wear resistance and long life

In the compressor section, the newly unsaturated hydrocarbons must be cooled quickly to prevent undesirable reactions occurring lowering overall yield. Considerations for the quench tower level control valve include:

- spring-and-diaphragm actuators increase stability

- rotary valve designs provide streamlined flow passages

- trim versatility allows seal replacement without removal of ball or actuator

- trim materials should resist erosion

Reliable operation of the cracked gas compressor is critical.

If the compressor or turbine trips due to excess vibration, malfunctioning instruments or surge, it can bring the entire operation to a halt for multiple days.

For these centrifugal compressors, surge is a condition where the flow reverses. Anti-surge valves:

…recycle gas from the outlet to the inlet of the compressor to ensure a high enough rate of flow. These valves must respond quickly and accurately to prevent severe damage to the compressor.

Read the article for considerations for these anti-surge valves as well as the considerations for the critical control valves in the recovery section of the ethylene and other olefins production process. Visit the Emerson.com Ethylene page for applied solutions with respect to blowers, boilers & combustion processes, compressors and cooling towers.

You can also connect and interact with other control valve and petrochemical processing experts in the Valves and Chemical groups in the Emerson Exchange 365 community.

Update: Updated the olefins picture to the one in the Fisher Olefins Solutions brochure.