I have a preview copy of Jyotsna’s presentation and will highlight some key points from it. The production field where this solution was applied had a process capacity of over 20,000 barrels of oil per day and over 2.5 million standard cubic meters of gas per day.

Key in meeting production levels approaching these capacities was effective well testing, which could provide real-time operational data that could be accessed remotely to this mostly unmanned platform.

Offshore platform test separator

Jyotsna noted other challenges in this installation that the producing wells had a high gas volume fraction (GVF) and stringent Health, Safety, and the Environment (HSE) standards.

Multiphase meters have several advantages over test separators. Measurement accuracy, reliability and repeatability are improved. This performance is independent of the flow regimes through the meter. Capital costs are lower from less process vessels, piping, valve work, etc. From an operational standpoint, production is not shutdown to switch production between test and production separators. Also, issues associated with liquid carryover and gas carry under (gas blowby) are avoided.

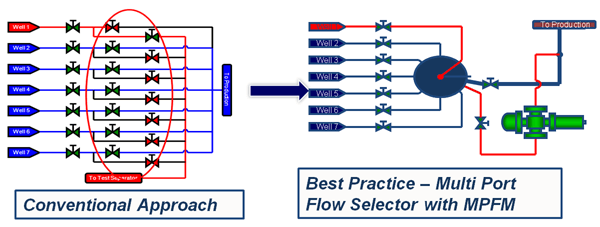

Jyotsna described the Emerson Multi-Port Flow Selector (MPFS) solution consisting of a Roxar 2600 multiphase meter, EIM multiport actuator (MPA), and Bettis multiport flow selector that allows the diversion of fluids from a single flow line into the test outlet or sampling device. The MPFS connects up to 7 flow lines. The combined fluid can flow through separate group outlet, while simultaneously isolating a specific well for testing. Up to 8 wells can be connected to a single MPFS.

Test separator approach vs. Multi-Port Flow Selector approach

Automated well testing is performed by the Roxar Fieldwatch application, which also provides diagnostics, data validation, and condition monitoring. The application can be accessed remotely to provide composition information of the producing wells back to operations personnel to make real-time production decisions.

Jyotsna closed her presentation noting that the highly automated solution helped the oil & gas producer to generate effective and accurate real-time well testing data accessible from remote control rooms and allow well production issues to be diagnosed in real-time to help keep the field producing at optimum levels.

There’s still time to register for the Emerson Exchange Stuttgart conference, so if you can, join us! If you can’t, subscribe to get daily email summaries from the event and/or follow the action at EmersonExchange365.com/Live.